Exceptional Handling Configuration SAP EWM

- Rajesh Sharma

- Nov 13, 2024

- 4 min read

Exceptional Handling Configuration in SAP EWM

The purpose of this blog is to state Exceptional Handling in SAP EWM.

Overview

Exceptional handling in SAP Extended Warehouse Management (EWM) refers to the processes and strategies used to manage and resolve unexpected situations that deviate from the normal flow of warehouse operations. These include discrepancies, damaged goods, incorrect quantities, on unforeseen events like system errors.

Exceptional handling in EWM is a powerful tool that allows many business requirements to be easily mapped without using enhancements. SAP EWM uses Exception Codes, which are called in event-driven transactions like Picking Confirmation, confirmation of Put-away Warehouse tasks, or Internal Warehouse Transfer Posting.

In EWM we would be having different environments.

Desktop Environment

RF Environment

Business context: Inbound/ Outbound/ Internal

Exception Codes

You can define exception codes to describe an exception situation in the warehouse. This exception situation occurs, for example, if the data that the system returns does not match up with the actual situation in the warehouse. You can use a short form of exception to communicate this to the system.

You can then simply save the information, or can use it to trigger the system to start a freely-definable follow-up action. For this purpose, there are connections available to the SAP workflow, the SAP alert framework, and the SAP status management.

The exception codes are only valid during the confirmation of product warehouse tasks within the picking process if the confirmation was started from desktop transactions.

You can create exception profiles to group special user IDs. If you don’t need any restrictions, then you can leave the profile blank when defining the exception code.

Note: The assignment of user IDs to the profile is not part of the configuration. You can make these assignments under settings.

1 Exception Codes for Outbound

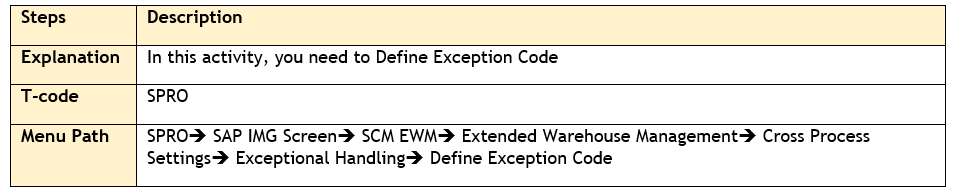

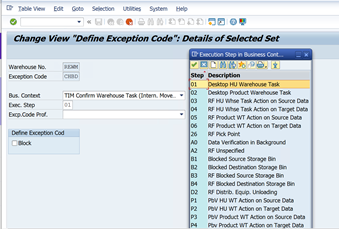

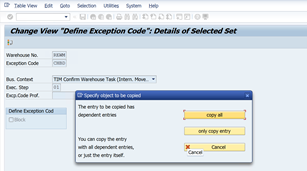

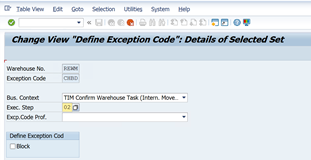

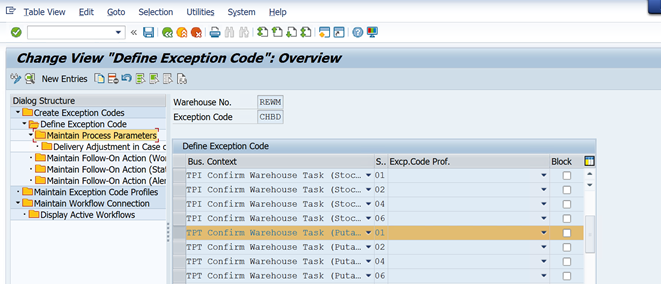

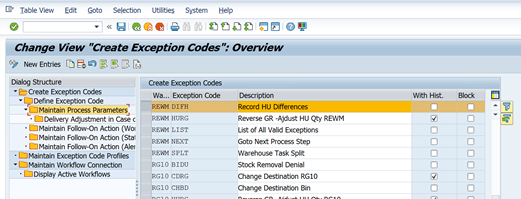

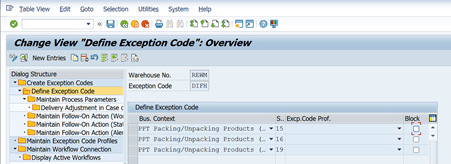

Step 1: Define Exception Code

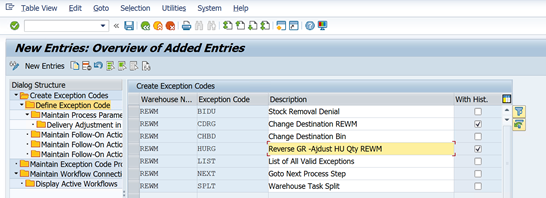

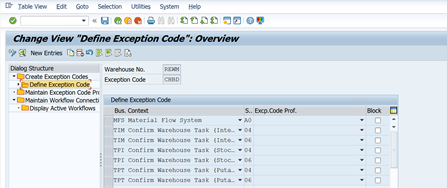

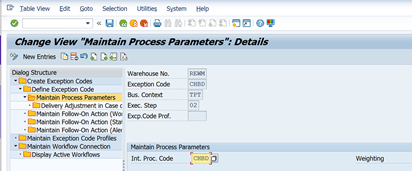

Step 2: Define Exception Code by making assignments to the business context, the process code, and the exception code profile

Example:

Business Context: TPI Confirm Warehouse Task (Stock Removal)

(Process mode) execution step: 02 Desktop Product Warehouse Task

Exceptional Profile: 0002 High Qualification

2 Exception Codes for Inbound

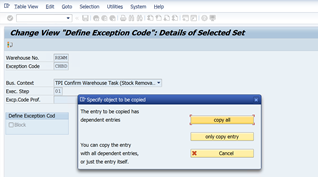

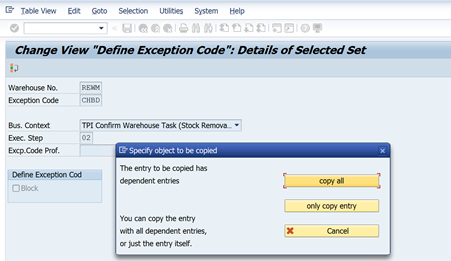

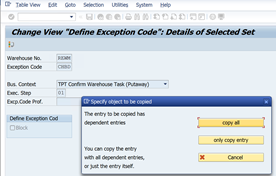

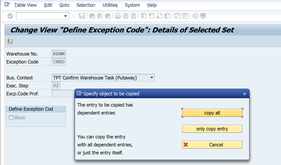

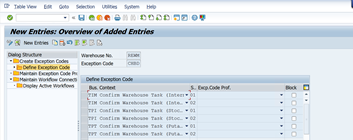

Step 1: Define Exception Code

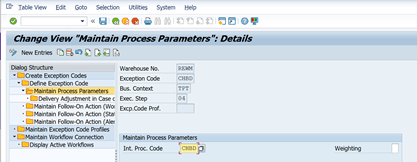

Step 2: Define Exception Code by making assignments to the business context, the process code, and the exception code profile

Example:

Business Context: TP: Confirm Warehouse Task (Put-away)

(Process mode) execution step: 02 Desktop Product Warehouse Task/ RF Environment

Exceptional Profile: 0002 High Qualification

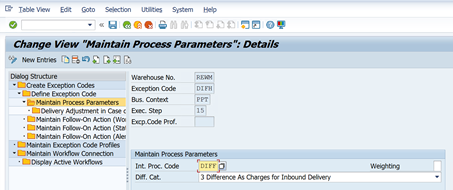

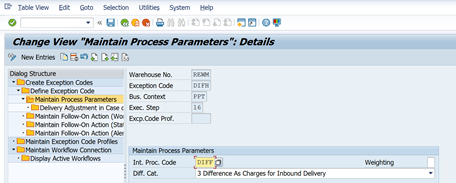

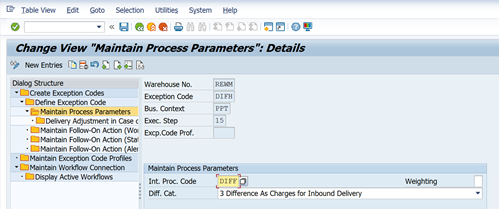

3 Configuration follow-up action

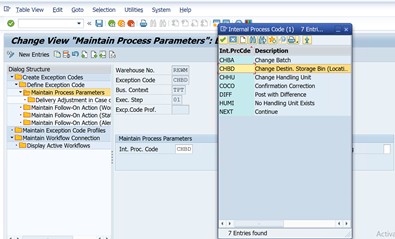

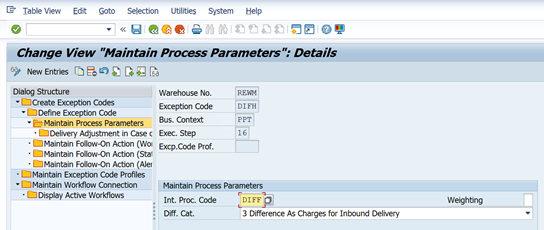

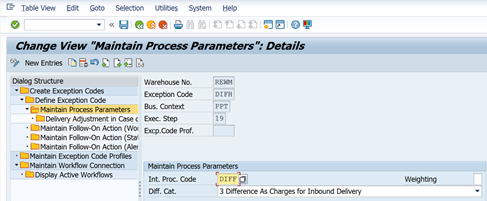

Step 1: Assign Internal Process Codes

Step 2: Assign a workflow start ID

Step 3: Assign a status management action ID

Step 4: Assign alerts including their prioritization (error, warning, information)

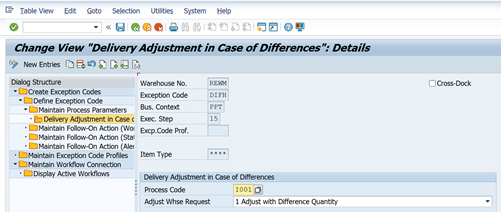

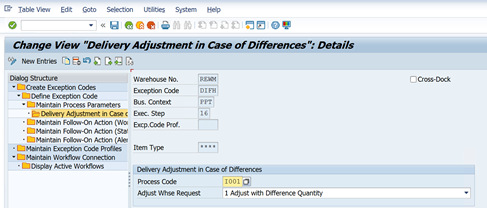

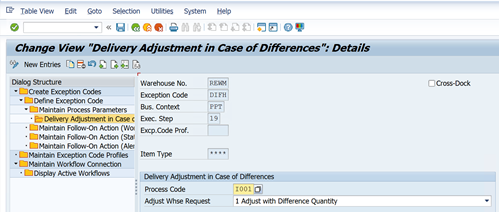

SAP delivers internal process codes that influence the behavior of radio frequency (RF) or desktop screens (CHBD- Change Source/ Destination Bin) or process differences) for example (DIFF, BIDF, or BIDP). The difference category defines the follow-up actions for the differences as follows.

1. Difference to Source Storage Bin

2. Difference to Difference Account

3. Difference in Charges for Inbound Delivery

Furthermore, in options two and three, you have to decide how the delivery is to handle the differences. We can configure in configuration of delivery.

Define Item types for the Inbound delivery process, they are valid for certain delivery item categories.

If you want the differences to work independently of the item category of the delivery, enter, ****, in the Item type filed in the dialog structure of delivery adjustment in case of differences.

You can create workflow starts IDs. You define these IDs by making assignments for persistent ABAP classes and their events including the workflow number.

You can assign available status management actions (block source bin for put-away) to influence the status of the affected object (bin) or you can set the customer specific user status. Exception handling supports the status change for bins and handling units.

You can assign the available alert types to categorize the alert displayed in the Alert Monitor.

Example:

1. RF Terminal:

A warehouse employee has an order to remove 100 pieces from a storage bin. However, the storage bin is not accessible. After the employee enters an exceptional code, the system calls a screen that allows the employee to enter a new destination storage bin.

2. Paper Order:

A warehouse employee has an order to put away 100 pieces into a storage bin, However, the storage bin is currently in maintenance. After the employee enters an exceptional code. The system sends an alert to the warehouse manager and the storage bin is blocked for put away and stock removal.

4 Test Configuration of Exception Codes

In this IMG activity, you can test the configuration of the exception codes.

Choose the business context, the process mode, and the relevant application (warehouse task, warehouse request, PI document), so that you can verify the settings made for the exception code.

When checking the exception codes, the system logs the essential information and displays it on the screen.

When an exception code is executed, either a test workflow is started or an alert is written, depending on your configuration.

You can go directly to the work center to check whether the workflow has been started.

You can go directly to the Alert Monitor to display the alerts that have been written.

5. Configuration Steps

4.1 Define Exception Code

Conclusion

The above steps need to be followed to configure the Exceptional Handling in SAP EWM

Credit

This blog writing inspiration is from Naidu Sir's Live EWM Training Recorded Videos at SASTRAGEEK.

Rajesh Sharma

SAP WM/EWM Functional Consultant

§ Linked in profile: https://www.linkedin.com/in/rajesh-sharma-204910278/

§ Twitter: RajeshS98151512/ RAJESH SHARMA@RAJESHS21287609

§ SAP Blogs: https://www.sastrageek.com/blog

Comments